Cartridge filter manufacturers believe in making the best products available and know it is feasible to provide the industry with different grades of product based on the type of pool/hot tub, geographic location, what water quality challenges (if any) the customers are facing. Unfortunately, unlike other industries, the aquatics sector has a ‘one size fits all’ approach. That said, to get past this ideology, there is a need for a new consumer rating system, which would help consumers and businesses properly size and install pool filtration systems accordingly.

What consumers expect from a filter cartridge?

In a survey conducted by the authors’ company, pool and hot tub owners, retailers, service technicians, and distributors were asked what they expect from a pool/hot tub filter. It was based on three main performance characteristics:

- Clean water (a.k.a. turbidity reduction).

- Longer operational cycle (a.k.a. service life of the product).

- Longer product life (a.k.a. dirt holding capacity).

Today, pool and hot tub filter manufacturers use these parameters of performance to build next generation products for the industry.

No two pools are the same—from the way they are plumbed, their surroundings, and the manner the customer uses them. Therefore, it is difficult to use a one-size-fits-all approach. One good example of this is a 151,416-L (40,000-gal) pool in Florida would use an 11.1-m2 (120-sf) cartridge filter, while the same size pool in Arizona would use a 39-m2 (420-sf) filter. There are a couple of reasons, for this. The frequent sand and dust storms and other climatic conditions requires the pool owner in Arizona to have a filter cartridge system with higher dirt holding capacity compared to someone in Florida.

Until recently, filtration systems for pools and hot tubs were only classified on micron ratings—giving customers a choice between cartridge, diatomaceous earth (DE) grids, or sand filter media. Typically, filters are rated by its micron size, which indicate the absolute largest particle that is capable of passing through the media. Filters designed for applications such as drinking water or air quality are expected to catch debris (to the rated value) as it passes through the filter media. Since there is no expectation for the same water or air to be recirculated, the filtration must happen during the first (and only) pass.

However, this is not the case with pool and hot tub systems. Aquatic filtration systems count on the repeated circulation of the same body of water, which builds a filter cake on the media. Over time, the filter is able to clear smaller and smaller particles. Eventually, all filtration systems will clear the pool to different degrees of efficiencies despite their differences in the initial micron rating.

To explain further, this article will look at the comparison of two filter cartridge systems:

- ‘System A’ housing a single 9.3-m2 (100-sf) filter element; and

- ‘System B’ containing four filter elements of 9.3-m2 (100-sf) each for a total of 37 m2 (400-sf) of filter area.

One would expect System B to perform four times better than System A; however, it is important to understand how each system’s performance characteristics are different.

Clean water (turbidity reduction)

Two, 757-L (200-gal) tanks were used, along with a challenge load, to make both systems built with the same filtration fabric, equally dirty. Identical equipment set-ups (i.e. same variable-speed pump (VSP), flow rates, plumbing layout), with the exception of the filter tanks, were plumbed to each tank. A turbidity meter, which measures the cloudiness of water, was used to confirm the starting turbidity of each test tank. The starting Formazin Turbidity Units (FTU) should be identical for both test rigs before the start of the experiment. The filter systems were allowed to run until they achieved the desired turbidity value.

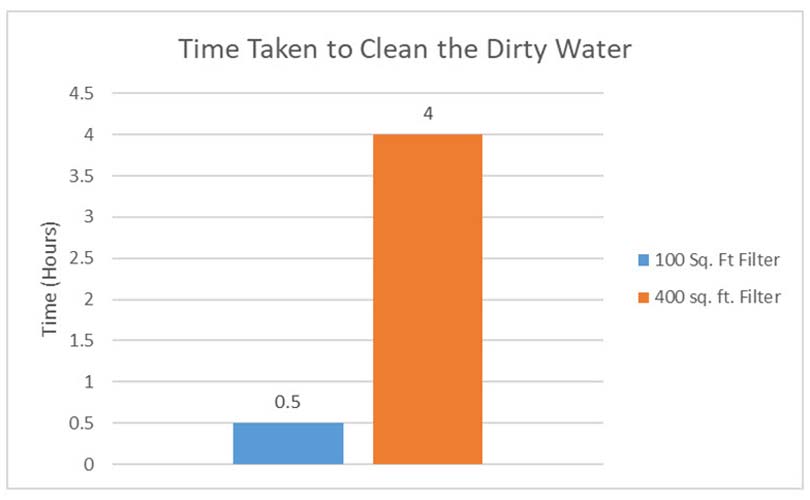

The challenge water consisted of dirt, DE, and oils and the result contradicted the ‘more is better’ approach (see Figure 1 below).

When considering the amount of filtration media, ‘System A’ was able to clear the challenge water faster than its counterpart ‘System B.’ This is because the 9.3-m2 (100-sf) filter could build filter cake very quickly compared to the 37-m2 (400-sf) filter elements. Once filter cake develops on the surface of the filtration material, it is able to capture finer dirt particles more efficiently.

Longer operational cycle (service life)

Customers or technicians do not want to service filters frequently. The industry standard is to service the filter (via either cartridge cleaning or backwashing) once the pressure on the filtration system has increased by 8 psi over the starting pressure. It is a given that as the filters are soiled, the pressure on the system increases and flow rate through the system decreases.

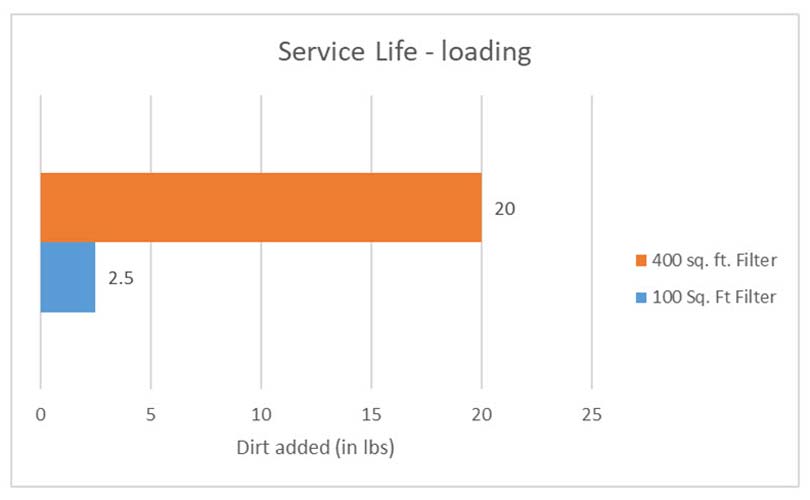

For this test, both systems were gradually loaded to increase the pressure using the same challenge load, which comprised roughly 0.2 kg (0.5 lbs) of a mixture of dirt and oils.

As one will see when evaluating a cartridge filtration system, having more media certainly delivers a greater amount of overall dirt holding capacity (see Figure 2 below). DE and sand filters are relatively fixed in their geometries (tank cross sectional area for sand and grid size for DE grids) so the amount of debris captured remains relatively the same.

Longer product life (dirt holding capacity)

Everyone desires longer product life when making an investment. The filtration system is not exempt from this. Unlike most industries where filters are disposable, in the pool and hot tub sector, filters are serviced regularly and re-used for as long as possible. Though the filter may never attain the same performance as when it was new, the client expects it to last a long time.

It is not easy to estimate how long a filter will last, since there are so many variables and no two pools are the same. The life of a filter is impacted by how well the pool water chemistry is maintained, what type of chemicals are being used for water treatment, other pool maintenance requirements, weather, algae blooms, and many other different situations.

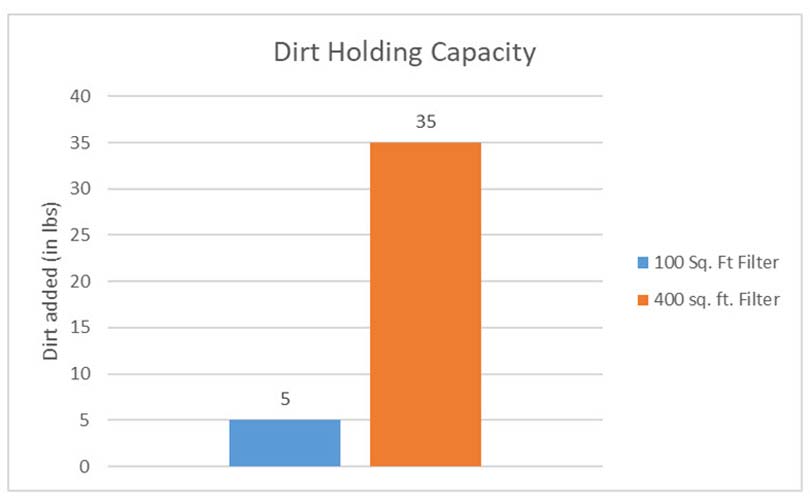

To find out how much dirt a cartridge will hold or withstand, the filter was not serviced for this part of the test, as the system was left to ‘max’ out. Today, most intelligent pool pumps will automatically shut down when there is very little flow through the system. Filtration systems for the most part are rated for 50 psi; however, most pools have limited flow beyond 30 psi (pressure as seen on the gauge of the filtration tank). If there is insufficient circulation in the pool, the water quality is negatively impacted.

For this part of the test, the challenge load was continually added into the tanks until the filter system pressure peaked at 30 psi. The final result showed ‘System B’ was capable of holding more dirt compared to ‘System A’ before both tanks reached 30 psi (see Figure 3 below).

The current standard for pool and hot tub filtration media needs to be updated to achieve what today’s consumers are expecting from the product. It also needs to be dynamic enough to accommodate the changing expectation of the market and consumers. All manufacturers want to build a product for future customers; therefore, the industry standard should allow and encourage companies to develop better products for the industry.

At the heart of the issue is the current pass/fail segment of NSF/ANSI 50: Equipment for Pools, Spas, Hot Tubs and Other Recreational Water Facilities to clear a body of dirty water by 70 per cent in five turnovers at different flow rates.

- Commercial flow rates for cartridge filters = 1.4 lpm (0.375 gpm)/sf of media

- Residential flow rates for cartridge filters = 3.78 lpm (1 gmp)/sf of media

These flow rates encourage the formation of filter cake at different rates that may not necessarily produce the desired clarity within the five turnovers specified. The standard penalizes larger-sized multiple-cartridge filter systems by expecting the system to accomplish the same clarity of water in five turnovers similar to a smaller single-cartridge filter system.

Therefore, the standard is encouraging the use of tighter medias for these same multiple-cartridge filter systems in commercial applications. To capture fine particles found in the test dust specified by the standard, filter manufacturers need to have a tighter filtration fabric, which may result in shorter cycle times and lower dirt holding capacity. This could be a concern to most pool owners and service technicians, as pool cartridges are not single pass filters. Further, customers may not desire a tighter or lower micron filter, as the filters will eventually capture finer particles with the buildup of filter cake.

Customers want better dirt holding capacity and longer cycle times to minimize the amount of cleaning. Servicing a filter could take anywhere from 30 minutes to two hours or longer depending on the method used to clean and service the filter system; therefore, cleaning frequency will affect the end user’s experience.

It is understood that reproducing a real-life pool environment in a test lab is not an easy task. The standard calls for the use of a silica-based challenge dust; however, challenging the products with real-world contaminants such as lotions and oils should not be ruled out. In a pool environment, swimmers will apply suntan lotion and/or tanning oil, which form a slick impermeable substance on the surface of the media and compromise filtration. These contaminants should be considered as part of an updated challenge debris to the standard.

The goal for manufacturers is to build a better product, while for consumers it is to buy a better product. To do this, the governing standards organization must go beyond what manufacturers are capable of producing to help qualify a better performing product for end users and, as a result, encourage manufacturers to raise the bar higher for the industry.

This article was written by Richard Medina and Abhi Pillai and originally appeared on Pool & Spa Marketing [link].