Salt chlorine generation has been used as a primary sanitizer in swimming pool applications as early as the 1960s. Today, there are more than three million salt-chlorinated pools around the world—a number that continues to grow significantly every year. Most systems can be found on residential pools but, within the last decade, this sanitation equipment has made inroads into the commercial pool market.

Historically, salt chlorine generators for commercial pool applications suffered from limited chlorine production rates, difficult and space-consuming installation requirements, and inadequate technology. However, as a result of increased consumer demand, along with a recognized increase in the hazards of chlorine transportation, storage and use, and lower pool sanitizer operating costs, salt chlorine generator manufacturers are developing simpler and more robust systems for the commercial pool market.

Past Practices

Salt chlorine generators for commercial pools have typically used high concentrations of salt (5,000 to 6,000 parts per million [ppm]) and intricate plumbing configurations that require multiple generating cells to provide adequate sanitization. However, commercial chlorine generators to date have been primarily based on existing residential chlorine generating equipment, which are naturally sized for much smaller bodies of water, with significantly less chlorine demand.

When applied to a commercial pool, multiple residential systems, comprised of several controllers and salt cells, must be plumbed together to deliver the requisite chlorine.

When applied to a commercial pool, multiple residential systems, comprised of several controllers and salt cells, must be plumbed together to deliver the requisite chlorine. The average residential pool size is approximately 75,000 L (20,000 gal) whereas the typical commercial pool in the hotel, motel, apartment, and condominium (HMAC) market can range between 150,000 to 189,000 L (40,000 to 50,000 gal).

Due to the higher bather loads associated with commercial pools, many salt chlorine manufacturers suggest the average outdoor commercial pool will require more than twice the chlorine as a residential swimming pool of the same volume. So how much chlorine is that exactly? It is suggested a 189,000-L (50,000-gal) outdoor pool will require approximately 454 L (120 gal) of 10 per cent sodium hypochlorite (NaClO) or 82 kg (180 lbs) of 65 per cent calcium hypochlorite (Ca[ClO]2 per month. Therefore, the chemical feed equipment would be required to deliver 15 L (4 gal) of sodium hypochlorite or 2.72 kg (6 lbs) of calcium hypochlorite each day in a 30-day cycle.

C4000 and Multiple Aquarites

Most commercial peristaltic chemical feed pumps and chemical erosion feeders are quite capable of meeting these chlorine production demands. Until recently, however, few equipment manufacturers have made an effort to produce chlorine generators that could yield these higher sanitizer rates using a single controller/single salt-cell system as has been the practice with residential pools. The most common high-output salt chlorine generators for residential pools produce approximately 0.6 to 1 kg (1.5 to 2 lbs) of chlorine per day, which is not nearly enough to satisfy the chlorine demands of the average commercial pool.

Multiple Residential Units

Without a simple chlorine generating system available for commercial pools, those facilities that recognized the benefits of using these systems, and had the available space within their equipment rooms, along with sufficient capital to invest, opted to install multiple residential chlorine generating units.

Without a simple chlorine generating system available for commercial pools, those facilities that recognized the benefits of using these systems, and had the available space within their equipment rooms, opted to install multiple residential chlorine generating units.

Oftentimes, due to installation space and complexities, the systems were plumbed in a series configuration. This meant the salt cells were plumbed inline one directly after another. While this type of installation has been widely practiced, it does not represent the most efficient or cost-effective method of reaping the true benefits of salt chlorination. Studies have shown, when salt cells are installed in this manner, the system’s efficiency can potentially become compromised as the water moves through each successive salt cell.

More specifically, as electrolysis occurs within a cell, salt concentrations are depleted (as salt is converted to chlorine) and gas bubbles are generated, which affect the performance of the next successive cell. Chlorine production is predicated on an expected concentration of salt in the water; therefore, having cells configured in a series can deprive successive salt cells downstream of the proper salt levels required for optimum chlorine production.

More critical, however, is the presence of gas bubbles, which can disrupt the ability of the dissolved salt to come in direct contact with the chlorine generator’s active electrode surface. Only at the surface of the electrodes can the salt be converted to chlorine. When salt cells are installed in sequence, gas bubbles significantly interfere with the key mechanism of chlorine production by blocking the active surface area. For this reason alone, manifolds using a parallel flow path through multiple cells should only be employed when it is necessary to install multiple systems on a given pool.

Another issue that has been troubling commercial pool operators who are interested in installing these systems is properly sizing the equipment. Due to the initial cost of the equipment, available space in the pump room, and the expense of having to install multiple units, many systems that were being installed in the commercial pool market were undersized relative to the pool’s chlorine requirements. In these situations, operators found themselves in a position of not being able to sanitize their pools properly during peak hours of operation, forcing them to temporarily close their pools.

Future Outlook

Salt chlorine generator manufacturers have recognized the need to provide equipment that not only satisfies the larger chlorine demands of commercial pools, but are also simple to install and compact in design. As a result, commercial systems that produce in excess of 2.26 kg (5 lbs) of chlorine per day with the use of a single-power supply and single-salt cell are now available. Further, the equipment footprint (both controller and salt cells) and their installation simplicity are comparable to residential units. With advancements in salt chlorine generating systems, coupled with a better understanding of their application in the commercial pool market, the use of this technology is more widely accepted. In fact, there is a significant demand.

What are the driving forces behind this trend?

The primary reason for the popularity of salt chlorination for commercial pools (and residential pools for that matter) are the three ‘Cs’—comfort, convenience, and cost. Salt chlorinated pools provide a level of bather comfort not realized in traditional chlorinated pools as the mild salinity of the water is closer to that of human skin cells and tears ducts (3,000 to 7,000 ppm), giving the water a softer, and more natural feel.

Additionally, because the equipment moderates the delivery of chlorine to the pool and prevents periods of low-chlorine concentrations, there are inherently less combined chlorines produced. Combined chlorines are the source of chloramines, which can create irritated eyes, itchy skin, and the chemical odours experienced in swimming areas. Studies have shown the excessive exposure to chloramines can result in breathing problems and even induce asthma among healthy individuals. For all the associated swimming comforts of a salt-chlorinated pool, many commercial pool owners/operators report their customers request their pool be converted to salt chlorination.

In fact, many owner/operators are generally happy to comply and make the conversion simply because of the convenience they are afforded by these systems. One clear cut example is the pool’s sanitization requirements become much more convenient as the need to haul and store heavy, corrosive, and sometimes flammable forms of chlorine are eliminated, or at least reduced significantly.

Further, owner/operators have also recognized the cost savings associated with making the switch. Pools maintained on standard chlorine sanitation programs are becoming more expensive to operate as chemical prices have increased dramatically in recent years. Using a sodium hypochlorite cost of $0.60/L ($2.25/gal), an average 189,000-L (50,000-gal) outdoor commercial pool (operated year-round) would consume more than $3,200 in chlorine per year. This is a significant cost of operation for a pool of this size.

On the other hand, salt chlorination has seen very little fluctuations in price in the last five years. New commercial salt chlorine generating systems are available that are less expensive than using multiple residential systems and yield the same or similar chlorine output. In estimating the annual operating costs associated with maintaining a typical commercial pool using liquid or tablet chlorine, and comparing it to the annual operating cost of a salt-chlorinated pool over a two-to-three year period, the costs are comparable. Despite the upfront expense associated with purchasing and installing the chlorine generating equipment, the money saved on an annual basis provides a quick return on investment (ROI).

Although switching to a completely different method of treating pool water may seem like a challenge, the process of converting from traditional chlorination to salt chlorine generation is actually quite simple. In fact, the switch does not require any other equipment changes in the pump room, nor does the pool need to be drained. With today’s advancements in chlorine generator technology, the introduction of this equipment into an existing commercial pool pump room has become quite simple.

Newer commercial salt chlorine generators make use of small 120-volt power supplies in conjunction with a compact, single-cell electrode stack that produces more than 2.26 kg (5 lbs) of chlorine per day, which is enough to handle the application’s peak demands.

Historically, these systems were manufactured to operate as their own entity and were quite difficult to integrate with automated pH and oxidation-reduction potential (ORP) chemical controllers. With the growing awareness of chemical automation due to the rising occurrences of waterborne illnesses and increased legislation, manufacturers have initiated ways to make the adaptation of water chemistry controllers seamless with commercial salt chlorine generators.

For example, most commercial units now have ‘plug-and-play’ options, where the chlorine generator has a primary power supply cable that plugs into a standard ground fault circuit interrupter (GFCI), and a separate male cable that plugs into an automated pH and ORP chemical controller. This setup allows chlorine levels to be maintained more accurately. Once the chlorine generator is plugged into the controller, chlorine is only delivered to the pool based on actual demand, not on percentages or timers. This not only keeps chlorine levels more accurate, but also simultaneously adjusts the pool’s pH level to ensure the water remains balanced for more active chlorine and safer bathing conditions.

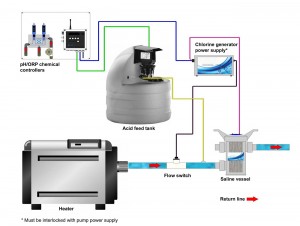

Commercial salt chlorine generator inline installation

Additionally, automated controller manufacturers have taken their technology one step further by providing the ability to control a salt chlorine generator as the primary source of sanitization, while offering the capability of controlling a secondary backup chlorination system with a separate ORP set point for added safety in commercial pools. This increases water chemistry safety as the chlorine generator is allowed to handle sanitation demands unassisted until the controller is made aware of an extraordinary situation where it will power an additional chlorine feed system to assist the chlorine generator to ensure safe water conditions.

Salt chlorine generating systems offers a great deal of benefits to the entire spectrum of stakeholders within the commercial pool market. As mentioned earlier, comfort, convenience, and cost-savings are the primary factors for this change. Each of these alone drives demand for the switch from traditional liquid/tablet chlorine as the primary sanitizing method for commercial pools.

The introduction of new technologies, ease of installation and operation, as well as increased product longevity, will now serve to play an important role in this paradigm shift. It appears chlorine generators are poised to become a common feature in the commercial swimming pool industry.

This article was written by M. Troy McGinty & Ray Denkewicz and originally appeared on Pool & Spa Marketing [link].